How to Repair Holes in Radiators (Plus Two Ways to Prevent Them)

Can Radiators Be Repaired?

We’re all used to our old cars or racecars having a leak or two. Pushing a little oil out of the valve cover gasket at high RPM or a little gear oil weeping from the third member will not ruin your night at the track or your road trip. However, a coolant leak can mean game over, especially if the leak is coming from the radiator itself and not just a loose hose clamp or soggy old radiator hose.

While the processes are trickier than just tightening a clamp or replacing a hose, radiators can (sometimes) be repaired, both with short-term “band aids” to get you back on the road or track, as well as long-term repairs, usually done at a radiator shop by someone who knows what they’re doing.

What Does the Inside of a Radiator Look Like

Before we get into repair, let’s talk about the parts of a radiator that may need to be fixed.

- Radiator Core: The core has tubes and thin metal fins. Coolant flows through the tubes, and air passes over the fins, cooling the fluid. Radiator 2 row vs 3 row designs use differing numbers of tubes in the core, but the concept is the same.

- Cooling Fins: These are the flat metal pieces that help cool the coolant by spreading out the heat. They increase the surface area to improve cooling.

- Radiator Tanks: The plastic or metal tanks at each end hold the coolant. The orientation is different on a crossflow vs downflow radiator, but the function is the same.

- Inlet and Outlet: The inlet brings hot coolant into the radiator, and the outlet sends cooled coolant back to the engine.

- Transmission Cooler: Some radiators also have a built-in cooler for the transmission fluid to prevent overheating.

- Cap and Overflow Tube: The radiator cap controls pressure. Excess coolant flows into the overflow tank through a tube when needed.

Plastic vs Aluminum Radiator

No conversation about leaky radiators is complete without discussing OE-style radiators that use plastic tanks and aluminum cores. These are famous leakers for several reasons. First, they use gaskets to seal the surfaces where the plastic tanks meet the core. This method is made worse by the fact that plastic and aluminum have different rates of expansion and contraction when they are heated and cooled. Also, the plastic is more likely to get brittle and crack after those innumerable heat cycles. Finally, and perhaps most obnoxiously, we’ve found that universal plastic and aluminum replacement radiators tend to have extra ports in the tank that need to be plugged with bypass caps, which always seem to leak after a year or two. If there’s an argument to be made in favor of these radiators, it’s going to center around cost. This style of radiator is generally treated like a consumable and replaced with another low-cost radiator when they inevitably fail.

All-aluminum radiators are not subject to the perils that come from dissimilar tank materials and gaskets. Instead, a high-quality aluminum radiator will feature stamped or fabricated aluminum tanks that are fully welded to the core. This virtually eliminates failures at this point. Some, like Speedway radiators, are manufactured using a process called furnace brazing, wherein the base metal of the radiator parts is uniformly heated before a solder is flowed into the joints. This eliminates the need for epoxy at these points and the pitfalls that are associated with it. While the upfront cost is going to be more than a parts-store plastic radiator, a quality aluminum radiator is going to last longer and be more dependable. We have found that that all-aluminum classic car radiators and racing radiators are an investment worth making, and one that greatly minimizes the chances that you’ll find yourself standing in a puddle of hot antifreeze in the pits or on the side of the road.

Why Radiators Leak

If you think about it, a radiator really is a worst-case scenario when it comes to car parts that get tortured. The more you understand about how does a radiator work, the more you appreciate their delicate nature. They heat cycle repeatedly, from whatever the ambient temperature is up to around 200 degrees, then back down again, over and over and over. And on top of that, as the coolant heats up, pressure builds in the system. This would be one thing if radiators were a thick casting like an engine block or cylinder head, but instead they’re made from very thin material to maximize the necessary heat transfer. On top of the pressure and heat, radiators can also fail because of improper or contaminated coolant and stray voltage causing electrolysis. When you think about the abuse that they suffer, it’s easy to understand why radiators can develop leaks over time.

How Does a Radiator Get a Hole in It?

In addition to the laundry list of radiator perils above, remember that radiators are typically right out in front of the car. They’re susceptible to rocks, bugs, birds, dirt clods thrown by other cars on a racetrack, you name it. And in case of a frontend impact, that radiator will be first to the scene of the accident. We’ve also seen radiators develop leaks from being improperly mounted, where either they’re mounted too rigidly and have to flex with the chassis, or clamps and core supports are not properly isolated and rub through a tank or tube. So, in addition to the pressure, heat, and stray electrons damaging a radiator from the inside, external environmental factors also can cause trouble for your radiator.

Diagnosing Radiator Leak

So, let’s say that your radiator has succumbed to one of the issues described above. Careful inspection is how to tell if you have a radiator leak or a simple issue like a loose clamp or cracked hose. When and where it’s leaking can tell you a bit about what needs to be fixed. First look (and hope) for those simple issues like a loose hose clamp, dried-out radiator hose or heater hose, or a loose trans cooler fitting. Once those possibilities have been eliminated, it’s time to take a close look at the radiator.

It's a common scenario to look under the car after it’s been sitting in the shop for a while and see a puddle of coolant under the car from the radiator leaking at bottom. Older radiators can get “soft” due to corrosion from improper coolant, insufficient maintenance, or just age and hard use. Once a radiator starts leaking from internal corrosion, repair will be like a long-term game of Whack-a-Mole, where stopping up one leak will only expose the next weak spot. Usually, replacement will be the best course of action here.

For a radiator leak on top, the list of potential culprits gets longer. If a leak is above the coolant line, it can also be sneaky as it will only leak when coolant is circulating and the system is pressurized. If your radiator is leaking from the top, the cause is less likely to be corrosion. Instead look for failures caused by overheating and excess pressure. This could mean a cracked tank or tube, failure of a gasket or epoxy joint, failing radiator cap, or leaky fitting if lines are plumbed out of the radiator tanks or filler. Don’t forget to check the overflow. When the cap pops open to relieve pressure, coolant is going to flow through the overflow line and into the catch can. Check all of these fittings, hoses, and containers as you’re making your diagnosis. If the leak is coming from the radiator itself and the rest of the radiator is deemed solid, a simple crack in an accessible location may be a relatively easy fix for the repair shop.

Also, don’t forget that many cars with automatic transmissions use the radiator as a transmission cooler. One or two tubes through the core are dedicated to transmission fluid supplied by cooler lines from the transmission and fittings into the tank. If you see transmission fluid leaking from the radiator, there is likely something wrong with this circuit. A leak here also means that it’s not impossible for coolant to be mingling with the transmission fluid, and this could end up being a bad deal for your transmission as well.

How Do You Fix a Hole in a Radiator?

For our purposes here, we’re going to divide radiator “fixes” by short and long term. A short-term fix will get you back to the garage or back out on the track for the next heat, but shouldn’t be counted on for much more than that. The long-term solution for how to fix an aluminum radiator or an old-school copper and brass radiator is a professional repair job that’s typically only worth the investment if you have a high quality or custom-made radiator.

The short-term version of how to fix a hole in your radiator that most of us have experience with, both good and bad, is adding some type of “stop-leak” to the coolant. These additives are meant to work from the inside of the radiator and the molecules are designed to stack up at the leak point, similar to the way blood creates a scab when you say…bust your knuckle on the radiator fins while wrenching. Does radiator stop-leak work? There are lots of these products out there and while none of them are going to work 100% of the time, it’s still wise to carry a bottle in the “radiator repair kit” as a part of your travel toolbox for emergencies.

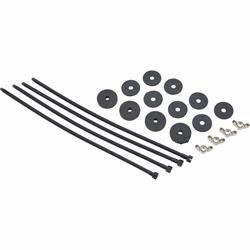

Another short-term fix that’s equally toolbox or trailer-worthy is a roll of “Stic-Tite” radiator sealant. This stuff works a bit like temporary solder, allowing you to seal a hole from the outside. To use it, first clean around the area of the leak as well as possible, then carefully heat the area until the epoxy melts into the hole. Just as with the stop leak added to the coolant, this is intended to be a quick fix to save the day on the road or night at the racetrack until a long-term repair or replacement can be made.

Long-term fixes will almost always be made by a radiator repair expert. The technician at the radiator shop can figure out the source of the leak and, based on what they find, make an honest recommendation of whether you should repair or replace. If you’re running a plastic and aluminum radiator, the answer will almost always be to replace. However, a quality copper and brass or all-aluminum radiator may be repairable. The chart below shows some possible issues and repairs.

We’re all hands-on folks here, and it’s always tempting to handle any issue that arises ourselves. “If you want something done right, do it yourself,” right? Well, in this case, we’ve found that it’s almost always best to let a pro handle a long-term radiator fix that you’re not going to be constantly worried about every time your car leaves the garage. As an example, consider a cracked tank on an aluminum radiator. While it may be tempting to fire up the TIG welder and fix it at home, remember what happens when there are contaminants in the base metal when you hit it with the torch. If the radiator has been in service, there is likely hidden gunk on the inside of the tank that will cause trouble for your repair attempt. A bubblegum weld may temporarily solve the problem, but a pro will be ready for issues like this and their repair will offer far more peace of mind down the road.

How to Protect Radiators from Getting Holes

While this article discusses your options if you find yourself with a damaged radiator, the most important point we can make here is to start with a good radiator and then protect it. You’ve heard the old adage that “an ounce of prevention is worth a pound of cure.” Well, that applies to your radiator as well. Here are couple tips to head-off trouble before it starts.

Use an All-Aluminum Radiator

As discussed above, plastic and aluminum OE style radiators are a leak waiting to happen. All-aluminum radiators don’t use gaskets or brittle plastic to seal the pressurized, 200-degree coolant speeding through them. Instead, the tanks, core, and filler are aluminum; far better suited to the abuse that radiators see every time the engine is brought up to temperature. This increased durability doesn’t mean that quality radiators can be left to the elements. Is a radiator guard necessary on a quality radiator? Yes, and even more so now that you have a radiator that’s worth protecting.

If you’ve made the investment in a high quality, all-aluminum radiator, here are some best practices to follow to maximize your radiator’s lifespan:

- Physically protect the radiator from environmental hazards like rocks and dirt with a radiator screen (more on this below).

- Tap water or well water contains minerals and chemicals that can damage aluminum radiators. Use 50/50 prediluted antifreeze, which is not only mixed in the proper ratio, but also is made with mineral and chemical-free distilled water.

- If you must use antifreeze concentrate, always mix with distilled water.

- Regularly flush the cooling system and replace the coolant with fresh antifreeze. The experts at DeWitts recommend using a quality five-year coolant and replacing it every three years.

- Protect the radiator from electrolysis by properly grounding all electrical components.

- Be careful with mounting. Rubbing on core supports and fan shrouds can wear through tanks and tubes if not properly isolated.

Protect Radiator from Rocks

Raise your hand if you’ve had a mysterious coolant leak, only to chase it down to a small hole in a radiator tube caused by a rock thrown by a semi out on the road or by another racecar at the track. If those little pebbles carry enough force to break your windshield, they can certainly puncture a thin piece of aluminum. Putting a layer of something tough out in front of the fragile radiator core is the best answer when it comes to how to protect a radiator from rocks and is cheap insurance for either a street rod or a racecar. Historically, expanded metal shaker screen radiator guards have done the job, but modern technology offers up some better alternatives. In particular, adding a Nomex radiator screen in front of your radiator core will offer protection from even the tiniest piece of debris. It’s also tough enough to take a hit from a flying dirt clod or even those nasty giant grasshoppers and junebugs that can wreak havoc when smacked at speed. Nomex is also easily trimmed to size. Are radiator guards worth it? Consider the cost of a simple Nomex radiator guard compared to the replacement cost of a radiator and the answer is pretty clear.

How Long Does a Radiator Last in a Car?

The answer to this question depends largely on the quality of the radiator, how well it’s maintained, and what its environment is like. If you ask the internet, the consensus seems to be that getting somewhere between 8-15 years out of a radiator is average. However, we need to account for the extremes in both directions. For example, a cheap aluminum and plastic radiator in a dirt Modified will likely measure its life in nights, not years. On the other end of the spectrum, we’ve seen flathead-powered 40’s Fords that still run the original copper and brass radiator, albeit one that’s been repaired repeatedly throughout its life.

Ultimately, a quality radiator, properly protected and maintained, will have a long service life and won’t be another thing that you need to worry about when you head out on the road or racetrack.