LS Engine Flexplate Fitment Guide

Knowing LS Flexplate Differences Will Avoid Frustration and Damaged Parts

For over 20 years the LS has been GM’s sole gasoline V8 offering (we won’t get into the semantics of LS vs LT engines here) and they have absolutely stolen the show when it comes to engine swaps. From classic muscle cars and pickup trucks to hot rods, kit cars, and more, the LS swap is common place these days. However, for those that opt for two pedal motivation, ensuring you have the correct LS flexplate for the type of transmission you’re bolting up to your 4.8 LS, 5.3 LS, 5.7 LS, 6.0 LS, 6.2 LS, or 7.0 LS engine. Thankfully things aren’t as complicated as the earlier small block Chevy V8, but there are still things to watch out for.

How Many Teeth Are on A LS Flexplate?

Chevy’s traditional small block used two different flexplate tooth counts with different converter bolt patterns across two different rear main seal types and engine balances. It’s enough to make your head spin with the different flexplates required, but if you’re planning a small block powered build, we can help you sort it all out in our SBC/BBC flexplate guide. The LS engine family does make things a bit easier for swappers by only using the larger 168 tooth flexplates. Keeping the LS engine family to one flex plate dimension and having all LS engines internally balanced greatly reduces the complexity of any swaps and means fewer parts differences for the manufacturer.

- See our LS flexplate dimensions diagram below in full size for easy viewing.

What Torque Converter Bolt Pattern Does the LS Engine Use?

While the LS engine uses a sole 168 tooth 14-inch diameter flexplate, it is available in two different torque converter bolt patterns depending upon what the factory transmission is behind it. For GM’s 4L60E, 4L65E, and 4L70E transmissions the torque converter bolt pattern is 11.062 inches. We’ve seen this listed everywhere from “11-inches” to “11.08-inches” depending upon the flex plate manufacturer and the source of the information. Just know it is the smaller pattern. GM’s 4L80E transmission uses a larger bolt pattern for its converter at 11.5-inches. If you plan to use the transmission that came with your junkyard LS swap engine you have nothing to worry about. Where things get a little tricky is bolting up an older GM transmission to the LS.

Many of GM’s older transmissions, including the Powerglide, TH350, and 700R4 use a 10.75-inch torque converter bolt pattern. This will require the use of a dual pattern flexplate or a custom LS swap flexplate that bolts to the LS crankshaft yet has the earlier pattern. This is a great LS to TH350 flexplate option. To successfully mate these two generations of parts a torque converter adapter sleeve is necessary due to the differences in the LS crankshaft’s dimensions and the dimensions of the converter hub. To make things simple we’ve created a LS to early transmission conversion kit with LS swap flexplate, hub adapter, and mounting bolts!

If you’re planning to bolt up a TH400 transmission things are a bit easier, as the TH400’s torque converter mounting pattern, at 11.5-inches, is the same as the modern LS when fitted with the 4L80E transmission. So, if your LS was fitted with the 4L80E transmission originally the only thing you’ll need to do is properly space your factory flexplate out with an adapter that places the LS flexplate in the proper location and supports the torque converter front hub. This spacer is a simple LS to TH400 flexplate option. This spacer is not required when fitting the TH400 to a 6.0L LS with long crankshaft (more on that below). If your LS was not fitted with the 4L80E from the factory, you’ll need to pair the adapter mentioned with the appropriate flexplate as well.

What If I Have a Long Crank LS Engine?

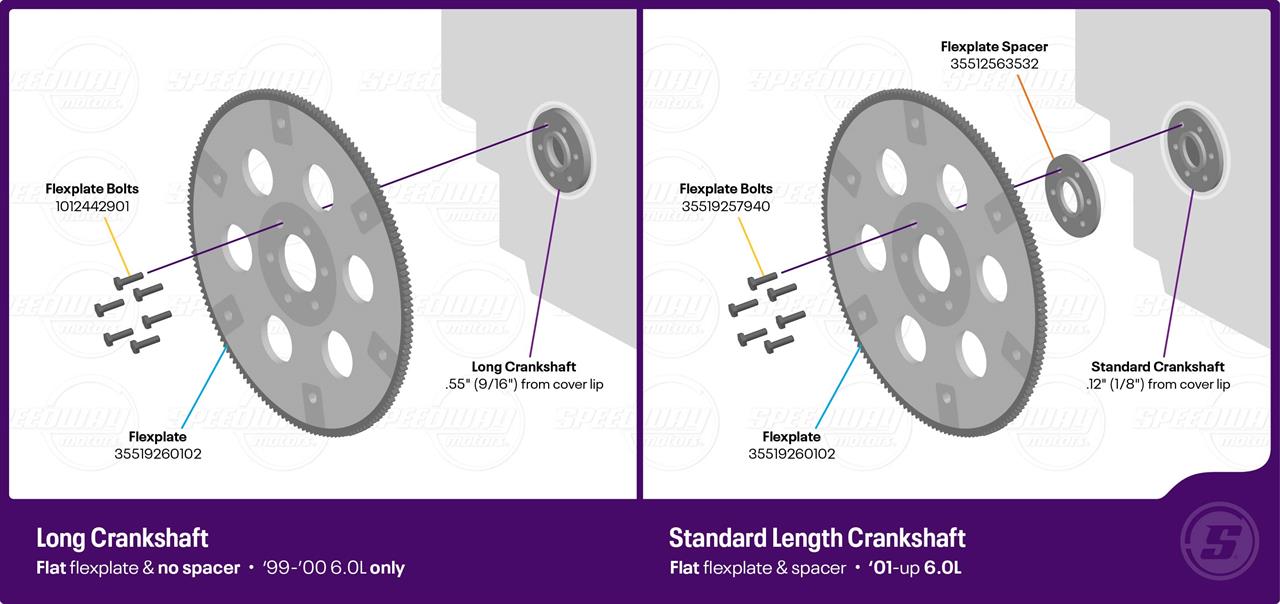

GM supplied the 6.0L LS truck engine in 1999 and 2000 with a crankshaft that has a longer rear flange than a standard LS crankshaft. This “long crank” LS does create a few issues when trying to bolt up certain transmissions, but most of them are easily solved either using the stock flex plate or swapping torque converters for the transmission. Identifying these “long crank” 6.0L engines are easy as all you need to do is measure the rear crank flange that is protruding past the rear main seal support. On “long crank” engines the flange will measure .55-inches past the seal lip, while a standard LS crank will measure .12-inches past the seal lip.

Notes:

To use a 4L80E transmission you simply retain the stock LS flexplate. If your flexplate is missing or damaged, we offer the correct flexplate to get you up and running. This flexplate will also support the TH400 transmission natively as well with no other changes.

To use the popular TH350 transmission the simple solution is to replace the TH350 torque converter with a TH400 torque converter. This is a direct swap with no other transmission modifications required. Adding the TH400 converter updates the TH350 to the required 11.5-inch bolt pattern and then will fit the stock flat flex plate used with these “long crank” 6.0L truck engines.

Unfortunately, there is no easy way to use a 700R4 or 4L60E (even an LS 4L60E) with the “long crank” 6.0L LS engine. The only real option is to get a 2001 or newer 6.0L crankshaft to install in your 1999 or 2000 6.0L engine.

See our LS crankshaft depth dimensions diagram below in full size for easy viewing.

What Do I Need for Newer LS Engines With 8-Bolt and 9-Bolt Crankshafts?

The 2008 and older LS engines used a 6-bolt crankshaft flange for the flexplate or flywheel. Beginning in 2009 the LS, LSA, Gen V LT, and LSX series engines moved to an 8-bolt crankshaft flange. Meanwhile, the LS9 went a step further with a 9-bolt crankshaft flange. To use any of these newer 8-bolt or 9-bolt crankshaft LS engines means once again choosing the proper flexplate or a converter swap to use a specific transmission. We’ll break them down further in our notes below. Many of these options are SFI flexplates, so you’re good to go when it’s time to hit the track as well.

Notes:

8-Bolt Options

- TCI offers a flexplate for 8-bolt engines to bolt up a 4L60E, 700R4, or TH350 transmission with no other modifications.

- You can also use a TH400 transmission if a TH350 torque converter with the 10-3/4” bolt pattern is installed in the TH400.

- To fit a 4L80E transmission to an 8-bolt LS engine a special order/custom torque converter will be required that is setup with the 4L60E’s smaller 11.06-inch pattern.

- The OEM flexplate from an LSA engine can be used with 6L90E transmissions

9-Bolt Options

- TCI offers a specific 9-bolt flexplate to add a 4L60E, 700R4, or TH350 transmission to your LS9-powered build.

- You can also use the same flexplate with TH400 transmissions by using a 10-3/4” TH350 torque converter.

So, there you have it. While not quite as complicated as Chevy’s earlier small block and big block flexplates, the LS is not without its own specific issues to watch for when it comes to LS flexplates. Knowing your crank bolt pattern, and torque converter bolt pattern/choice of transmission, and following this guide will set you on the path to LS swap flexplate success!