GM 10-Bolt Identification and Upgrades | 7.625, 7.5, 8.2, 8.5, 8.6

Read Time: 6 minutes

Article Summary: Learn how to locate, ID, and decode GM 10-bolt axles and explore upgrade parts.

When it comes to GM rear ends, there are two main designs: the 12-bolt and the 10-Bolt. While most hobbyists set their sights on the 12-bolt, the reality is that there are multiple versions of the GM 10-bolt rear end, one of which can hold 1,000 hp when built properly. With five versions of the GM 10- bolt, the field of options can be quite confusing. Dive into the differences between GM 10-Bolt rear end specs, rear axle identification codes, and rebuild tips.

How Much Power Can a GM 10-Bolt Handle?

There is but one high-performance GM 10-bolt rear end, the 8.5 (and identical 8.6). The other versions are severely limited in capabilities. Built from 1964 through 1972, the 8.2 models are capable of handling about 400 hp with street tires in stock trim, about 350 on drag radials, and 300 on slicks. When built for racing with a new differential, axles, and gears, you can send 500 hp through an 8.2 on street tries, with slicks, you are going to be limited to 400-450 hp. In 1971, GM began phasing out the 8.2 in favor of the 7.5 10-bolt, which was built from 1975 through 2005. In 1986, GM upgraded the 7.5 ring gear to 7.625 inch, but they are interchangeable. The smallest 10-bolt, the 7.5/7.6 can handle about 350 hp on street tires without major internal updates, and even then, it maxes out around 500 hp with maximum effort (and expense).

GM 10-Bolt Axle Identification I BOP 10 Bolt Axle

Identifying a GM 10-bolt rear end housing requires measurements, locating casting numbers, and knowing what to look for. The 8.5s and 7.5s look remarkably similar, so you’ll need a measuring tape to confirm. You can also check the RPO code list in the glovebox or trunk lid for the original rear, but you still need to verify the actual housing itself since it is easy to swap them out.

8.2 Housings:

The shape of the pumpkin (between the axle tubes) is smooth on the lower half of the case. The cover is either an 11-inch smooth cover or a 10-3/4-inch cover with a “hooded ridge” at the top that looks like a person wearing a beret. Weird description, but when you see it, you know exactly what we mean. The pinion nut is 1-1/8-inch. The axles are C-clip style.

7.5/7.6 Housings:

These are most found in 2nd and 3rd gen F-bodies (Camaro, Firebird), G-bodies (Regal, Cutlass), B-bodies (Caprice), mini vans, and S-series trucks and SUVs. They look very similar to the 8.5 models but are substantially weaker. The lower case has a pair of small lugs at 5 and 7 o’clock. The cover is oval-shaped, measuring 8-5/16 inches x 10-9/16 inches. To positively ID a 7.5 housing, measure the distance between the lower center bolt at its neighboring bolts, which should be 3-1/4 inches. The pinion shaft is 1.438-inch.

8.5/8.6 Housings:

The best 10-bolt, the 8.5 and later 8.6 design can be found in the following GM vehicles:

- 70-77 GM A-body

- 70-96 B-body

- 75-78 E-body

- 70-81 F-body

- 70-79 X-body

- 79-08 GM Trucks/SUVs

With so many potential sources, an 8.5/8.6 GM-10 bolt axle is not a challenging thing to find. At the bottom of the pumpkin at 5 and 7 o’clock, are two large square lugs with vertical sides. The covers are either an 11-inch with a ring gear bulge or 10-5/8-inch with an irregular shape in the upper right corner. The distance between the lower center bolt and the adjacent bolts is 3-3/4 inches. The 8.5/8.6 pinion nut measures 1-1/4 inches. The carrier (differential) uses left-hand threaded 7/16-20 bolts for the ring gear. The pinion shaft is 1.625 inches with 28 or 30 splines. Most 8.5s have C-clip axles, but there is a BOP (Buick Oldsmobile Pontiac) variant built from 1971-72 that has bolt-in axles. These are exceedingly rare, only found on certain Buick GS/Skylark, Oldsmobile Cutlass, Pontiac Grand Prix, and a few found their way to Chevrolet Monte Carlos. The occasional A-body wagon also got the bolt-in version. These are almost impossible to find, many of these vehicles were crushed without saving what many consider to be the absolute best version of the 8.5 10-bolt.

GM Rear End Identification Codes & Casting Numbers

There are several ways to identify a GM 10-bolt axle, from the carrier type and size to the gearing, GM rear axle RPO codes, and plant codes.

On most housings, the codes are located on the front side of the passenger or driver axle tube, about three inches from the pumpkin. You will often find casting numbers on the pumpkin as well, but the ID numbers are usually on the axle tubes. For 1970 and earlier, GM used a slightly different code system that 1971 and newer. We have two examples of the codes below showing the differences between them. See the attached chart for a full breakdown of plant, date, and differential codes.

1970 and earlier rear with code CB 05 27 W G

- CB- Axle ratio

- 05- Build Month

- 27- Day of year

- W- Assembly Plant

- G- Posi-traction source code (Detroit G&A Posi)

1971 and later rear with code CBG1121E

- CB- Axle ratio

- G- Build Plant

- 112- Day of year

- 1- Shift

- E- Posi-traction source code (Eaton Type)

Pro-Tip: The GM 10-bolt axle ratio codes vary by year, so creating a list of the ratios would take pages and pages. To get a definitive answer on the ratio of a rear housing, the best way is to pull the rear cover and look at the pinion gear. All GM 10-bolts are stamped with the ratios in the form of tooth-count. The code lists the pinion teeth and then the ring gear teeth, for example a gear set with “13-40-GM” is 3.08:1. Divide the ring gear teeth (40) by the pinion teeth (13), and you get 3.0769.

GM Rear Axle Width Chart

Various vehicles have different widths, so the housings are built to match.

GM 10-Bolt Differential Identification Chart

10-bolt carriers, otherwise known as a differential, are gear-specific, this means that only certain ratios fit each carrier. These are typically 2- or 3-series carriers. The difference between each series is the depth of the gear engagement (deck height), the mounting pad (deck) for the ring gear is thicker for lower gears (numerically higher). To find the deck height, place the carrier on a table with the driver-side axle down (the gear pad should face up), and measure the height from the table to the deck pad.

For most hot rodders, the 3-series carriers are the go-to choice. You can buy specialty gears that fit a 2-series carrier outside of the original range but using a stock carrier for high-performance or off-roading in a 7.5 or 8.2 is ill-advised, they simply are not strong enough.

GM 10-Bolt Differential Type Identification

The differential style, open or limited-slip, can be determined in a few ways. If the rear end is assembled, you can simply spin one wheel (or axle) and watch the other side. If the wheel/axle spins in the same direction, it is a limited-slip diff. Should the other wheel spin in the opposite direction, it is an open differential. You can also test the rear in a running vehicle by doing a burnout. If you leave two stripes, you have a Posi (Limited-Slip or LSD). This is not always definitive though, as a worn-out LSD might only spin one tire, and a crusty open diff can spin both tires without a load. This also does not work on the later truck model with a G80 “Gov-Lock” differential.

To visually confirm an LSD diff, remove the rear cover and look at the carrier itself. During this era, most GM LSDs were clutch type, either flat or cone. Regardless of type, all clutch type differentials have either an S-spring or 4-coil springs between the side gears inside the differential. You can see this clearly with the cover removed. An open differential just has a set of spider gears with a solid bar between them.

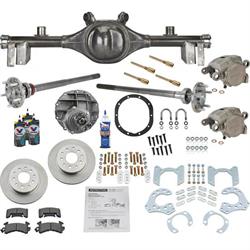

GM 10-Bolt Rear End Parts Diagram

GM 10-Bolt Rebuild Upgrades

If you are running more horsepower and torque than the original spec, you may quickly exceed the power handling of a stock 10-bolt, especially for 8.2” and 7.5” models. Upgrades are readily available for all models of GM 10-bolt rear ends, including lockers, LSD (Limited Slip), drop-in lockers, gear sets, GM 10 bolt disc brake conversion kits, GM 10 bolt mini spool kits.

8.5/8.6 GM 10-Bolt Rear End Rebuild

The 8.5 10-bolt in stock form can handle a lot of power, in fact the Buick Grand National unit can handle 9-second passes while hanging the front wheels; it is stout. The best upgrades for an 8.5 model are 30-spline axles (most factory 8.5s are 28-spline, some Oldsmobile models have 31-spline), with a new LSD differential, lower (numerically higher) gear set to better suit the use, and a full rebuild including new bearings. This will wake up your vehicle and bring the performance up to the level you expect. For maximum performance, consider adding the upgrades below as well.

8.2 & 7.5/7.6 GM 10-Bolt Rear End Rebuild

The smaller 10-bolts are inherently weaker, and unfortunately cannot be brought up to the same level as the 8.5 version. These rears have 28-spline axles, and there are no upgrades to 30-spline. The above changes are also the best option for the 8.2 and 7.5 variants, but these weaker rears need a few other items to get the maximum performance. The differential bearing caps can move around under high load, so a special high-performance cover girdle with adjustable bearing cap supports is needed. These supports are threaded rods that put a bit of preload on the bearing caps, providing more stability. We offer 8.2 10-bolt rear end upgrade kit pieces, including brakes, differentials, covers, and more.

The next upgrade is a housing support girdle. These are weld-on braces that provide extra support for the narrow axle tubes, which helps reduce flex and twist in the housing itself, which in turn, helps keep the axles aligned, reducing the chances of breakage.

C-Clip Eliminators

Most GM 10-bolts use C-Clips to retain the axles. These are C-shaped rings that slide into grooves at the end of the axle shaft in the center of the differential. Should the clip or axle break, the entire wheel and axle can slide out of the housing, which is a catastrophic failure. A common upgrade for any C-Clip axle is an eliminator kit. These are bolt-on kits that use an aluminum block that retains the rear axles in place like a standard bolt-in axle, should there be a failure.

These are often considered a great upgrade by many enthusiasts, but these are NOT suggested for any vehicle that gets driven on the street. The issue with these C-clip eliminator kits is that they are not strong enough to handle the side load when a 2-ton vehicle is turning. Eventually, the block deforms, causing leaks, and can put extra strain on the bearings, leading to premature failure. DO NOT install eliminators on any street-driven vehicle, it is a bad idea, regardless of your friend saying they have had no problems.

The better solution is replacing the housing ends with weld-on “Big Ford” ends, which requires custom axles. This converts the standard C-clip retained axles to a bolt-in style without the failure-prone eliminator blocks. This also requires Ford-style rear brakes, which are readily available.

GM 10-Bolt Rear End Rebuild Kit

Unless the rear end has been rebuilt recently, it is always a good idea to do a full rebuild when upgrading your differential. New bearings and seals reduce friction and bring the axles and components back into correct alignment with each other. A wheel bearing failure can lock up the affected axle, putting you at serious risk. Any gear change requires replacement of the pinion bearings, so you might as well replace them all. A master rebuild kit includes all the bearings, seals, crush sleeve, shims, gaskets, and grease paint for setting the gear mesh and backlash.

GM 10-Bolt VS 12-Bolt

The GM 12-bolt rear end is one of the most popular rears for GM vehicles (and many others with a swap), but the 12-bolt is just 3/8-inch larger than the 8.5” 10-bolt. Swapping a 12-bolt can be done on most vehicles that came with a 10-bolt rear but finding a 12-bolt that will directly bolt in is problematic, because the car 12-bolt was only made from 1964 to 1972; there just are not enough out there. The truck 12-bolt is not the same as the car version either.

Rear Axle Swap | What is a Ford 9 Inch and Why is it so Popular?

At the end of the day, the GM 10-bolt is only capable of handling so much power, even less if you’re running drag radials or slicks, as they put a real shock on the axle and driveline components. You’ll spend an awful lot of time and money building a 10-bolt rear that might survive a hard launch on slicks with 400 or so horsepower, but what if you’re putting out 600 or more horsepower? It is not that hard to do these days with a mild LS build and a turbo (or two!) to see 700 plus horsepower. One hard launch spooled up on the boost and your 10-bolt will be in pieces on the starting line. At this horsepower level it is wise to put your rear end build funds towards a better, more capable rear.

If you chose to swap out the rear end, your best bet is to always go with an aftermarket axle with stronger, fully welded housings that use better/thicker materials, such as the Speedway 9-inch housing. The Ford 9-inch rear housing is an excellent solution for most vehicles. Unlike the GM housings, all Ford 9-inch units have bolt-in axles that are available in much larger spline counts, with no C-clips to worry about. The differentials are not built by a series number, meaning any gear ratio will fit the same carrier. Aftermarket 9-inch housings are made for almost every popular make and model, including GM vehicles, making the 9-inch the go-to option for most builders. Lastly, the removable center section of the venerable Ford 9-inch allows for easy gear changes simply by swapping the “pumpkin” out, unlike an integral carrier housing like the GM 10-bolt.

How Much HP Can a Ford 9 Inch Handle

Aftermarket housings are fairly strong. Most Ford 9-inch units can easily handle 600hp or more, with reinforced units (back bracing, etc.) capable of handling over 1,000hp. The differential carriers themselves can handle the power. Of course, a strong differential housing is a must as well and ours are built to take the power with nodular iron construction, a Daytona pinion bearing support, and forged steel bearing caps

Speedway Motors offers direct swap Ford 9-inch axle assemblies for many GM muscle cars and pickups originally fitted with the GM 10-Bolt axle. Below are our most popular applications:

- 55-57 Chevy Car 9-Inch Swap

- 64-67 GM A-Body 9-inch Swap

- 68-72 GM A-Body 9-inch Swap

- 67-69 GM F-Body Multileaf 9-inch Swap

- 67-69 GM F-Body Monoleaf 9-inch Swap

- 70-81 GM F-Body 9-inch Swap

- 62-67 GM X-Body, Multileaf 9-inch Swap

- 68-72 GM X-Body Multileaf 9-inch Swap

- 67-72 C10 9-Inch Swap w/ Stock Perch

- 73-87 C10 9-Inch Swap w/ Axle Flip

- 73-87 C10 9-Inch Swap w/ Stock Perch

- 88-98 GM C1500/K1500 9-Inch Swap w/ Stock Perch

- 88-98 GM C1500/K1500 9-Inch Swap w/ Axle Flip

See all our GM-specific 9-inch axle assembly swap offerings, including full kits with brakes and fully loaded differential carrier, for the widest selection for your GM project vehicle.